Hotline:18057555982

Hotline:18057555982

Hotline:18057555982

Hotline:18057555982

News Information

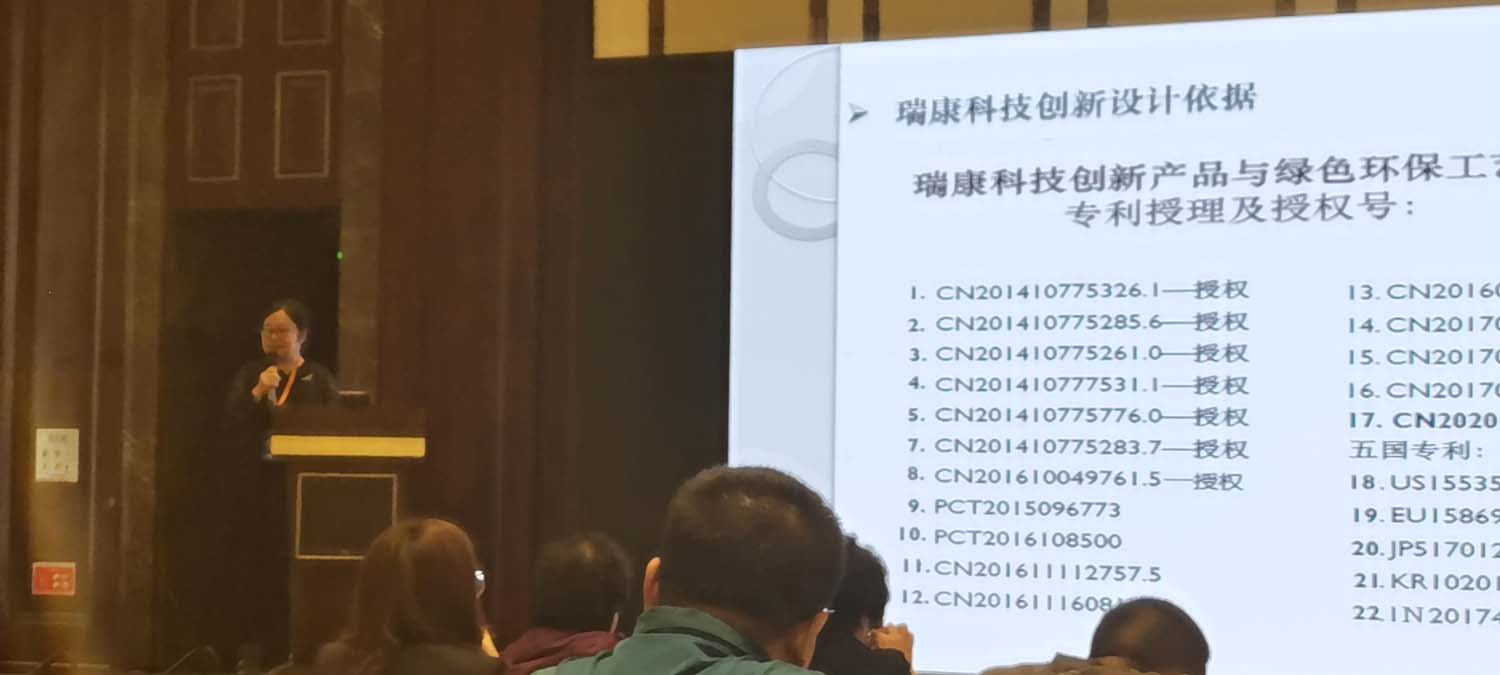

On November 17, 2020, at the China synthetic resin new material industry development conference, Dr. Mao Lijuan, chairman of Shaoxing Ruikang, released the latest accepted invention patent achievement at the conference: the research and application of space steric adjustable weak alkaline light stabilizer. This achievement was designed and invented by Dr. Mao himself and led the R & D team of Ruikang after more than five years of arduous efforts, It subverts the functional structure of tetramethylpiperidine amine light stabilizer that has been used for half a century, and introduces the original innovative space resistance adjustable weakly basic innovative stabilizer, which makes the development of new materials obtain more choices and opportunities.

Ruikang sincerely thanks the conference for providing such an opportunity and the leaders of the Ministry of science and technology for their appreciation of Ruikang's innovative inventions.

The patent acceptance number and name issued by this conference are as follows:

Patent acceptance No.: 202011250638.2

Patent name: structure, preparation method and application of space steric adjustable weak base light stabilizer

The acceptance of this invention patent marks that Ruikang team has taken a big step in the field of new polymer materials under the leadership of Dr. Mao Lijuan, which is of historic turning significance and the pride of Ruikang team.

Of course, this is only the first step of the long march. The application and promotion of Ruikang's achievements in the future development of the new material industry and their wide application depend on the joint efforts of all sectors of the industry to realize the real social value of Ruikang's innovative achievements and technologies in practical application. Ruikang team is always ready to meet every challenge and every opportunity. Ruikang has never stopped on the road of innovation.

On June 19, 2020, Shaoxing Ruikang Biotechnology Co., Ltd. was invited to attend the Linjiang Economic Development and work safety Conference in Qiantang New District. Dr. Lijuan MAO , chairman of our company, and General Manager Shubai Liu attended the conference.

This conference was jointly held by The Management office of Linjiang High-tech Park and Linjiang Street. The meeting pointed out that the new District would take the "new materials" industry as the strategic guidance, strengthen and improve the three pillar industries of fine chemicals, high-end equipment and biomedicine, and build a "1+3" diversified industrial system of Linjiang.It is emphasized that the development of Linjiang should take economic development as the first goal and safety and environmental protection as the first responsibility.

At the meeting, Dr. Lijuan MAO, chairman of our company, was invited to complete the construction project of Ruikang Innovative polymer functional auxiliary production base which was officially settled in Linjiang New District. The project signing ceremony officially started the construction project of pilot production base and took a group photo.

Chairman, says Dr Li-juan MAO, the success of the project contract, production and construction of our company in the new area and explore the positive role of the market, Ruikang will always adhere to the path of independent research and development innovation, strives to make a new material functional additives and related supporting materials, improve the competitiveness in the field of international market in China, the implementation technology industrialization, product internationalization, actively contribute to the high quality of economic development. At the same time, Ruikang will unswervingly respond to the call of the conference, always adhere to the concept of green chemistry, adhere to the use of the optimized green technology, firmly hold the bottom line of safety and environmental protection.

On March 31, Jianhua Zhu, a columnist of the overseas edition of People's Daily, came to our company for a visit and inspection and a discussion and exchange.

Chairman of the company Lijuan Mao led Jianhua Zhu to visit the company, introduced the innovation process of our company, and detailed the achievements of Ruikang in R&D, innovation, industrial development, demonstration and application of high-performance polymer functional additives.

In the symposium, the two sides discussed the development of functional additives and related industries of polymer materials in China. Jianhua Zhu said that new materials have become a new power to change the world pattern, but domestic high-end polymer materials and key additives are heavily dependent on imports, the development of related industries is not optimistic, with independent intellectual property rights of high-end polymer products and technology is imminent.

In recent years, the high-performance polymer functional AIDS developed by Ruikang through independent innovation, especially the series of long-acting high-performance polymer antioxidants, have far exceeded the product performance of the international large companies in comparison with the corresponding products in the market, and all Ruikang products have independent intellectual property rights of invention patents.

Jianhua Zhu spoke highly of Ruikang's innovative products. He said Ruikang's products have wide application fields and broad market prospects, and he is willing to help Ruikang biology to accelerate the industrialization of scientific research results.

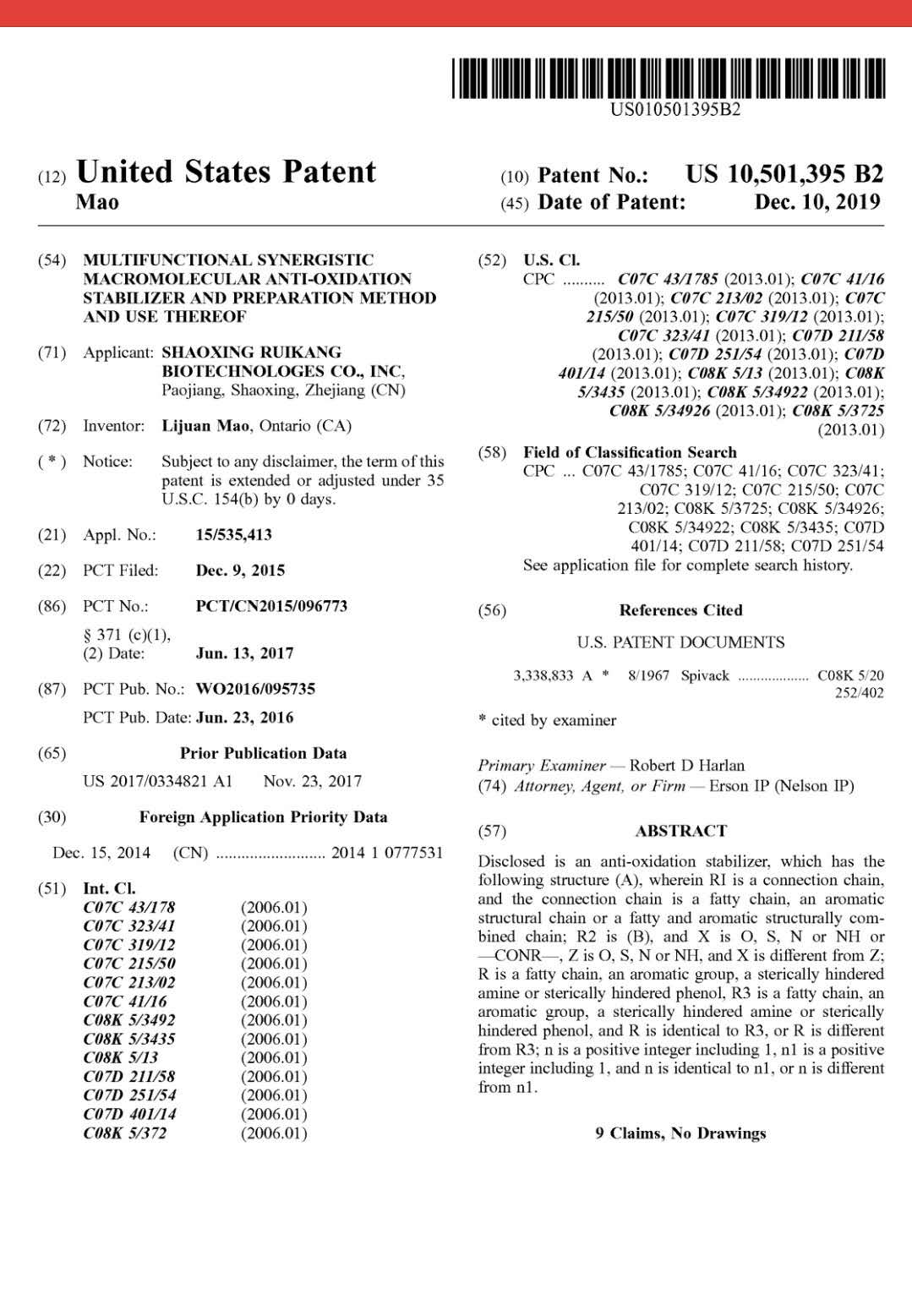

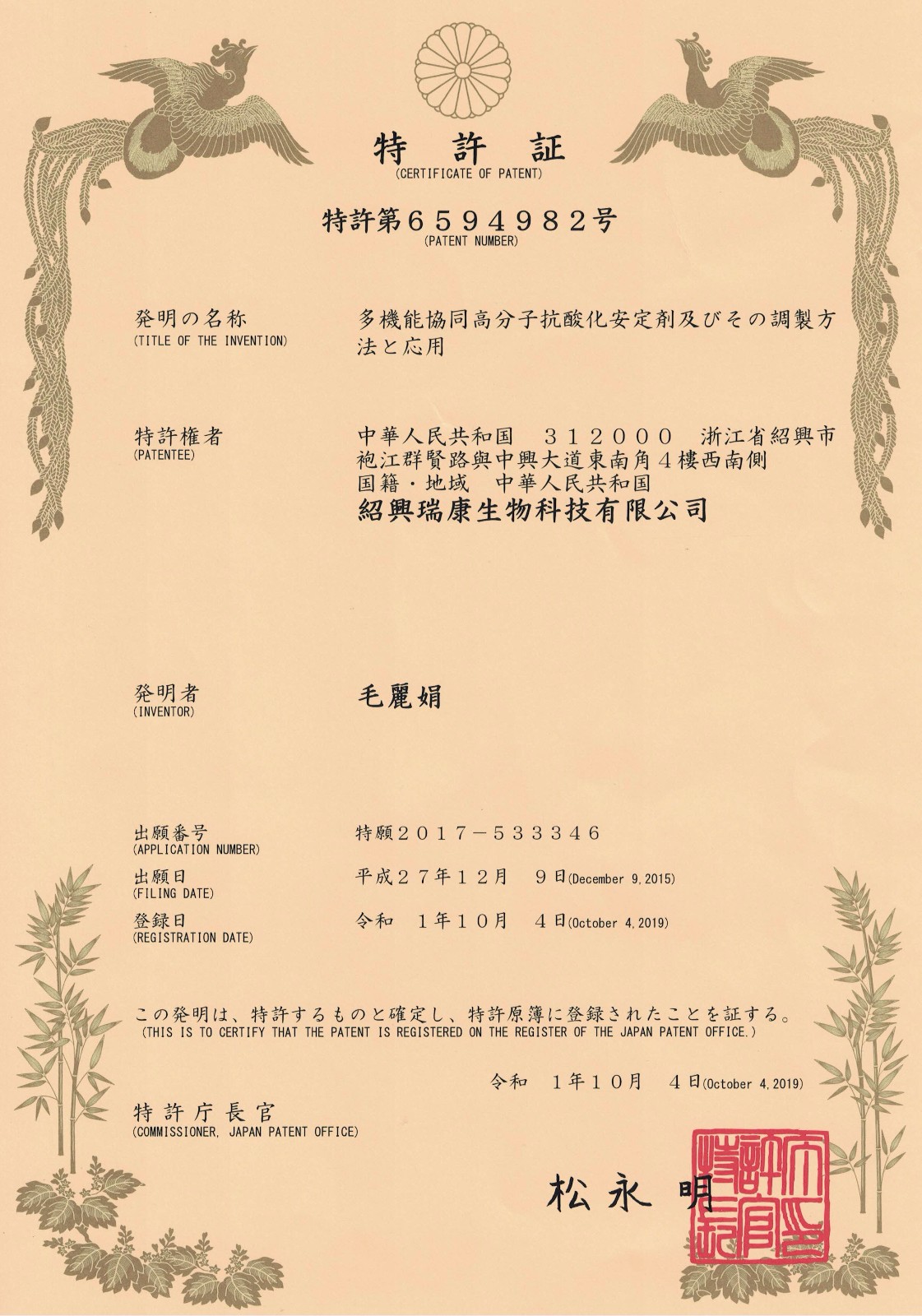

Recently, the invention patent of “MULTIFUNCTIONAL SYNERGISTIC MACROMOLECULAR ANTI-OXIDATION STABILIZER AND PREPARATION METHOD AND USE THEREOF” applied by the research and development team of Shaoxing Ruikang was formally granted in the United States and Japan. Us Patent NO. :US1050139582, Date Of Patent: December 10,2019; Japan Patent NO.: 6594982, Date Of Patent: October 4,2019.

As early as March 23,2016, the patent has been granted domestic authorization, Domestic Patent Number:ZL201410777531.1.

(1) Long-term Effective High-temperature Antioxidants:

· Type A products (ACANOX LT): with both anti-yellowing and long-term effective high-temperature anti-oxidation properties.

This type of products is suitable to utilize in light color plastic PP, PE, ABS, POE, HIPS, TPO,PBT, PU, EVA, and the related copolymers. They can be also used in light rubber, coatings and paints.

They are compatible to other polymer additives very well.

· Type B Products (ACASORB UV): with excellent long-term effective high-temperature anti-oxidation properties and UV light stabilization properties.

This type of products provides very effective protection to darker color of PP/talc, PP/Glass Fiber and other polymeric products, such as PE, ABS, PVC,POE, HIPS, TPO,PBT, PU, EVA, and the related copolymers. They can be also very effective to rubber and coatings. They are compatible to other polymeric additives very well.

(2) UV Light Stabilizers and UV Absorbers-Good Wheatherability Products:

· Type A Product (ACSTAB UV1) : Optimized Formulation with two composites, it showed good anti-yellowing properties and very good weatherability properties.

This type series of Ruikang's products to PP, PE, POE, EVA, HIPS, TPO, ABS, etc. provides very good weathering resistance with good anti-yellowing properties.

· Type B Product (ACSTAB UV2): Optimized Formulation with three composites, It showed excellent anti-yellowing and outstanding weathering resistance proerties.

This series of products provided excellent UV stabilization with outstanding anti-yellowing properties to PP,PE, POE, EVA, HIPS, TPO, ABS, PBT, PU, PA, and the related copolymers.

· Type C Product (ACASTAB UV3): Optimized Formulation with two composites, It showed very good weatherability with excellent anti-oxidation properties.

This series of products is suitable to be used for protection of dark color plastics and rubber products from UV light degradation and high temperature service thermal aging.

(3) UV Light Absorption Products:

· Type A Products ACSORB UV1: This type of UV adsorption products filtered UV light from 200 nm to 380 nm.

This type of products can be used for weathering requests in PP, PE, POE, PS, ABS, PU, PA, PBT and related copolymers products.

· Type B Products ACSORB UV2: This type of UV adsorption products filtered UV light from 200 nm to 360 nm

· This type of products can be used for weathering requests in PP, PE, POE, PS, ABS, PU, PA, PBT and related copolymers products.

· Type C Products ACASORB UV3: This type of product light adsorption from 250-420nm, it is suitable to be used as light adsorption of construction glass.

· Type D products ACASORB UV4: This type is blue light absorber from 200-500nm, it is suitable to be used as light adsorption of electronic devices screen.

(4) Multiple Functional Binding/Coupling Agents (ACASOLV MF):

· Type A Product (ACASOLV MF1): This type of products is polymeric additives which can form good connections between inorganic filler and organic polymers so that make it well dissolved each other. ACASOLV MF1 can be utilized in inorganic powder or glass fiber as filler in plastics and rubbers products. It can make stable bridge connection between inorganic fillers and organic polymers.

· Type B Product:(ACASOLV MF2): This type of products is polymeric additives which are able to couple with inorganic hydroxy functional group and its long organic moiety tangled with polymer. it functions as coupling agents.

ACASOLVE MF2 can be used as coupling agent in glass fiber and other fiber fillers plastics and rubber products.

(5) Functional Silicone (ACASILON ):

· Type A Products (ACASILON 1): This type of products is polymeric additives, it has shown good properties in processing, dispersion and stripping mold.

This type of products can be used in PP, PE, PVC, ABS, PA, PU and the related copolymers with different fillers.

· Type B Products (ACASILON 2):This type of products is polymeric additives with functions improving products' surface hardness and brightness.

This type of products displayed very good anti-scratch properties and controllable brightness on the surface of plastics and rubber products. It can be used in PP, PE, PVC, ABS, PA, PU, and the related copolymers.

Long-term Effective high-temperature Antioxidant

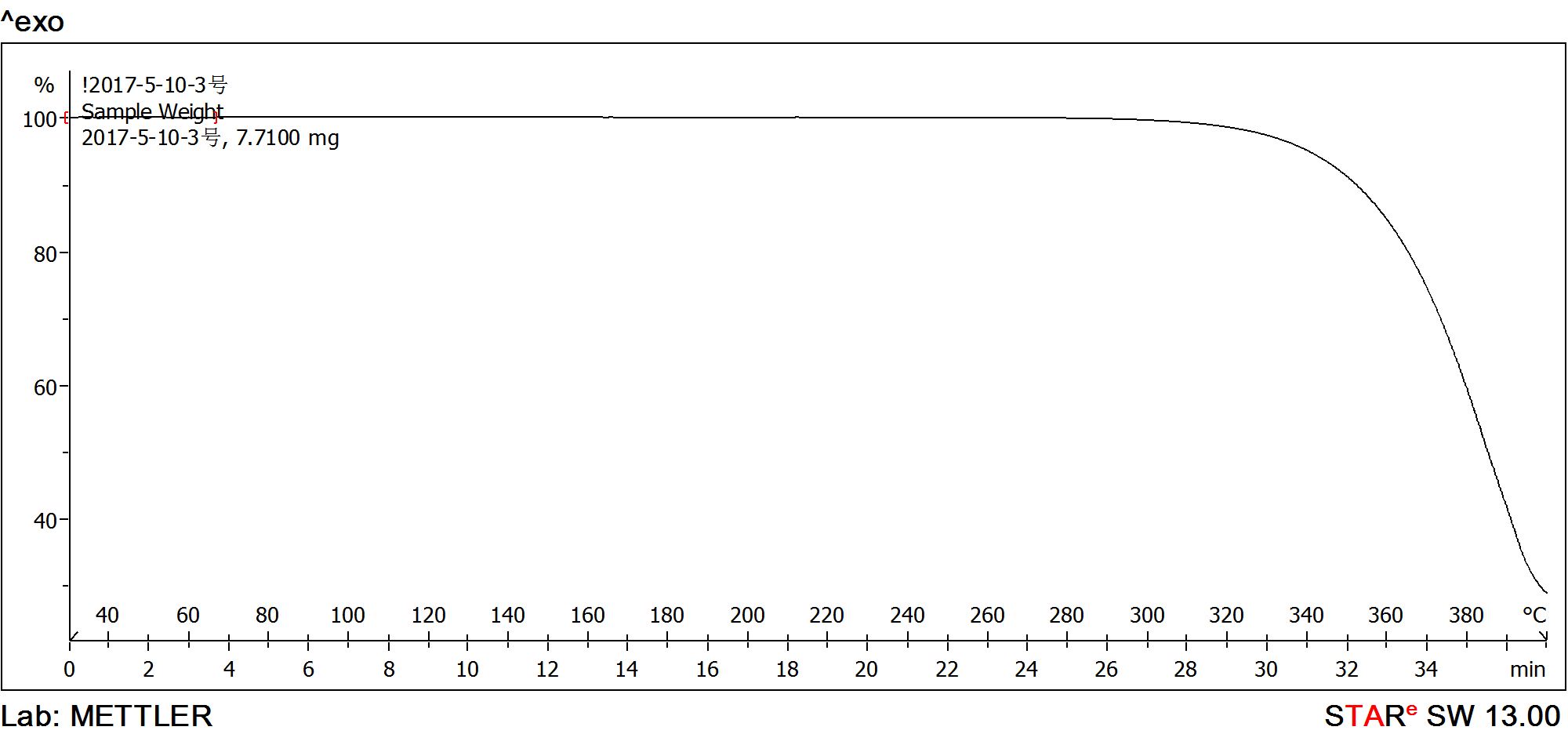

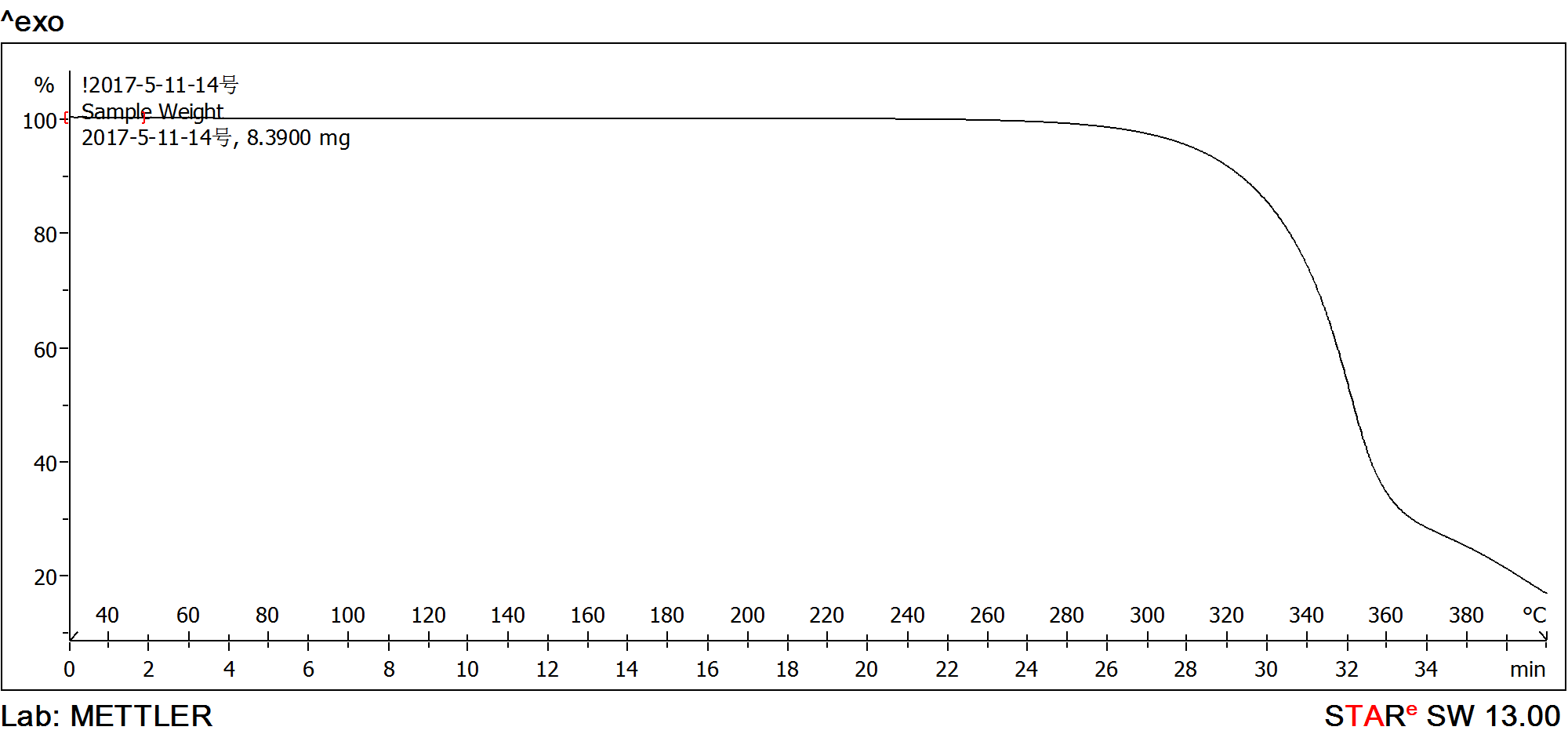

Physical Properties: All the series of ACANOX LT products are white or off-white powder, soluble in organic solvent, melting points are in the range of 125-140oC.

Conditions for Thermo-Aging Test in Oven:

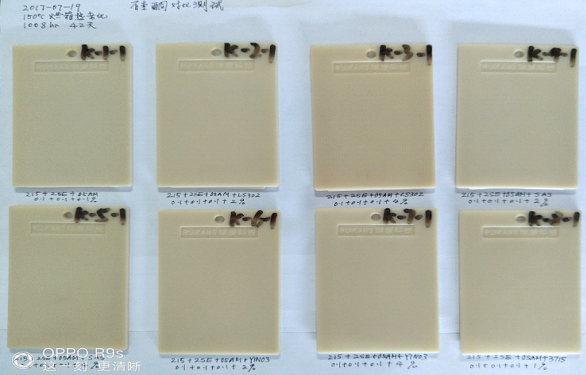

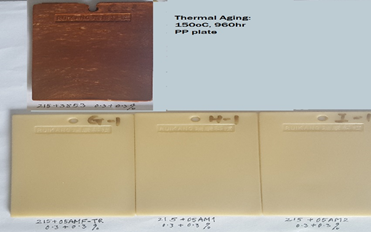

Polymer Plate: PP /Talc 20%, 150 oC, 2500 hrs, Antioxidant 215: 0.3%, Versus BASF DSTDP & ADDIVANT 412S

Long-term Antioxidants: 0.3%

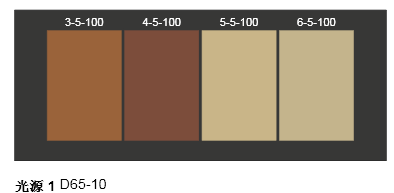

105th day's colorimeter Photo

Note: On the above photo pictures #3 plate contains DSTDP; #4 plate contains 412S; the rest plates

contain Ruikang's Long-Term Effective High Temperature Antioxidants (see Plate #5 and #6).

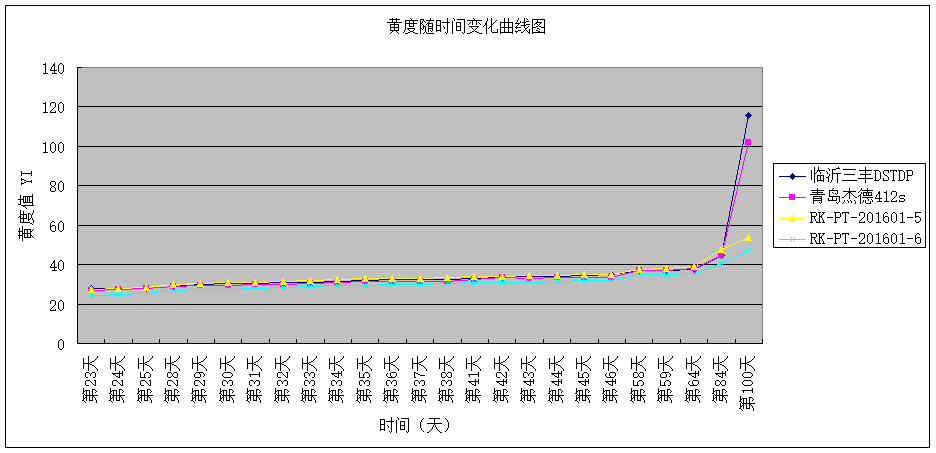

Note: On above graphic curve, yellowing index of #3(DSTDP) and #4(412S) plates rise rapidly in oven up to about 100 days and thoroughly pulverized, on the contrary, Ruikang's Long-term antioxidants showed much better protection to PP polymer Plates #5 and #6.

Conclusion: Ruikang's Long-term Effective High-temperature Antioxidants exhibited much better protection to PP polymer plates versus BASF's antioxidant DSTDP and ADDIVANT's 412S under conditions of Thermo-aging at 150oC, 2500hr, with addition amount of the long-term antioxidants 0.3% .

The Optimized formulations of Ruikang's Light Stabilizers

Physical Properties:The series products appear as white or off-white powder; Soluble in organic solvent, such as DCM, Ethanol, ethyl acetate; Melting Point: 56-75℃。

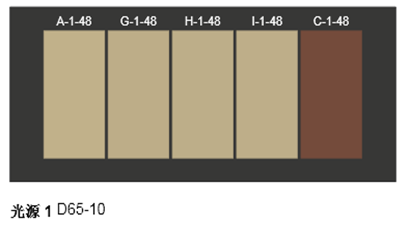

150oC Thermo-Aging Test in Oven:

PP-T20 plates, Antioxidant 215:0.1%, light stabilizer as shown

576hr result: The upper plate: Cytec's 3 products

576hr result: The upper plate: Cytec's 3 products

The lower are innovative Ruikang's formulations

1008hr results: The above plates are all Ruikang's

Optimized Formulations of light stabilizers with Ruikang's Silicone Polymer Additives

Conclusion: Ruikang's formulations have shown even much better anti-yellowing and anti-thermo-aging properties.

Products Applications: The series products are highly efficient light stabilizers with excellent thermo-aging properties, especially provide excellent protection for PP, PE, ABS, HIPS, TPO, POE, EVA and the related polymers, they also can be utilized in plastics, rubber, coatings, paints, etc. the products showed very good compatibility with polymers and displayed excellent synergistic function with other additives.

Package: 200g/per bottle, 5kg/per bag, 25kg/per bag, 50kg/per drum

Storage: room temperature, avoid light/heat/oxidants

Product Expiry Term: 24 months under nitrogen protection

They are used as Light Stabilizer of ACSORB UV Series Products

Physical Properties: The series of products are white to off white powder, soluble in organic solvent, e.g. DCM, EtOAc, ethanol etc. The melting point of the series products in the range of 50-80oC.

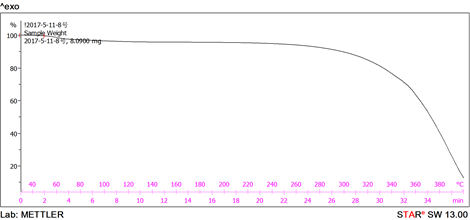

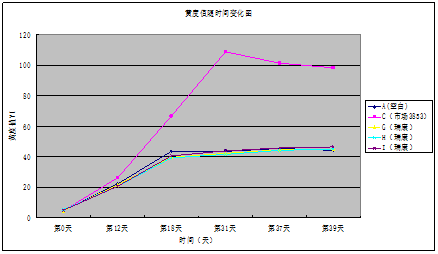

Thermo-Aging Test in Oven: Test Result for PP plate with our stabilizers, 150℃, 40 days(960hrs) is shown below.

Upper plate is added with market light stabilizer 3853, the rest are added with Ruikang's light stabilizers.

The far right plate is added with market light stabilizer 3853, the rest are added with Ruikang's light stabilizers.

Conclusion:Ruikang's light stabilizers have stronger anti-thermal aging properties compared to market's Light Stabilizer 3853.

Figure: Yellow Index versus Thermal Aging Time