Hotline:18057555982

Hotline:18057555982

Hotline:18057555982

Hotline:18057555982

News Information

热烈庆祝加入瑞康无毒抗菌剂的PP/PET薄片顺利通过接触食物的国际标准!!!

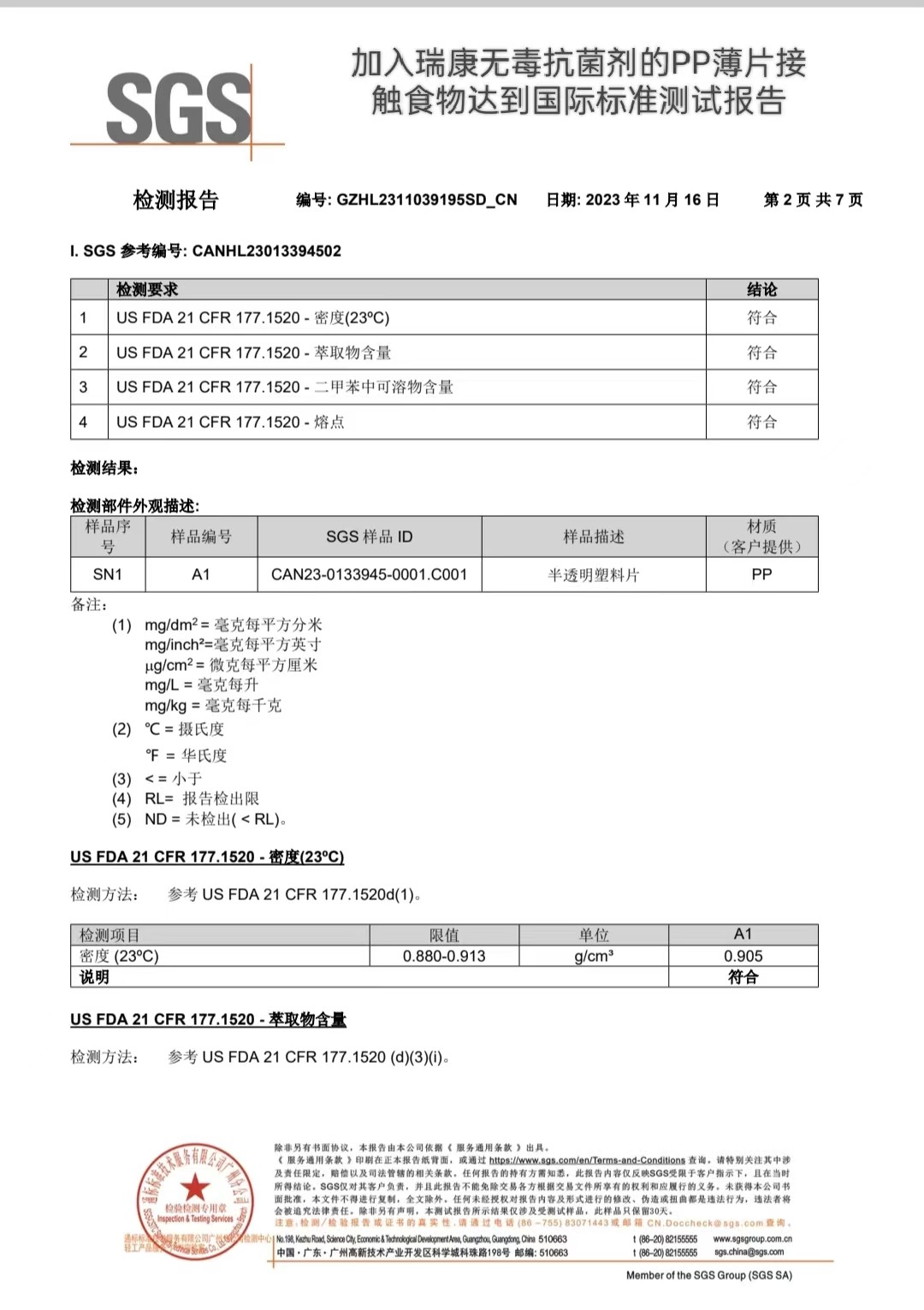

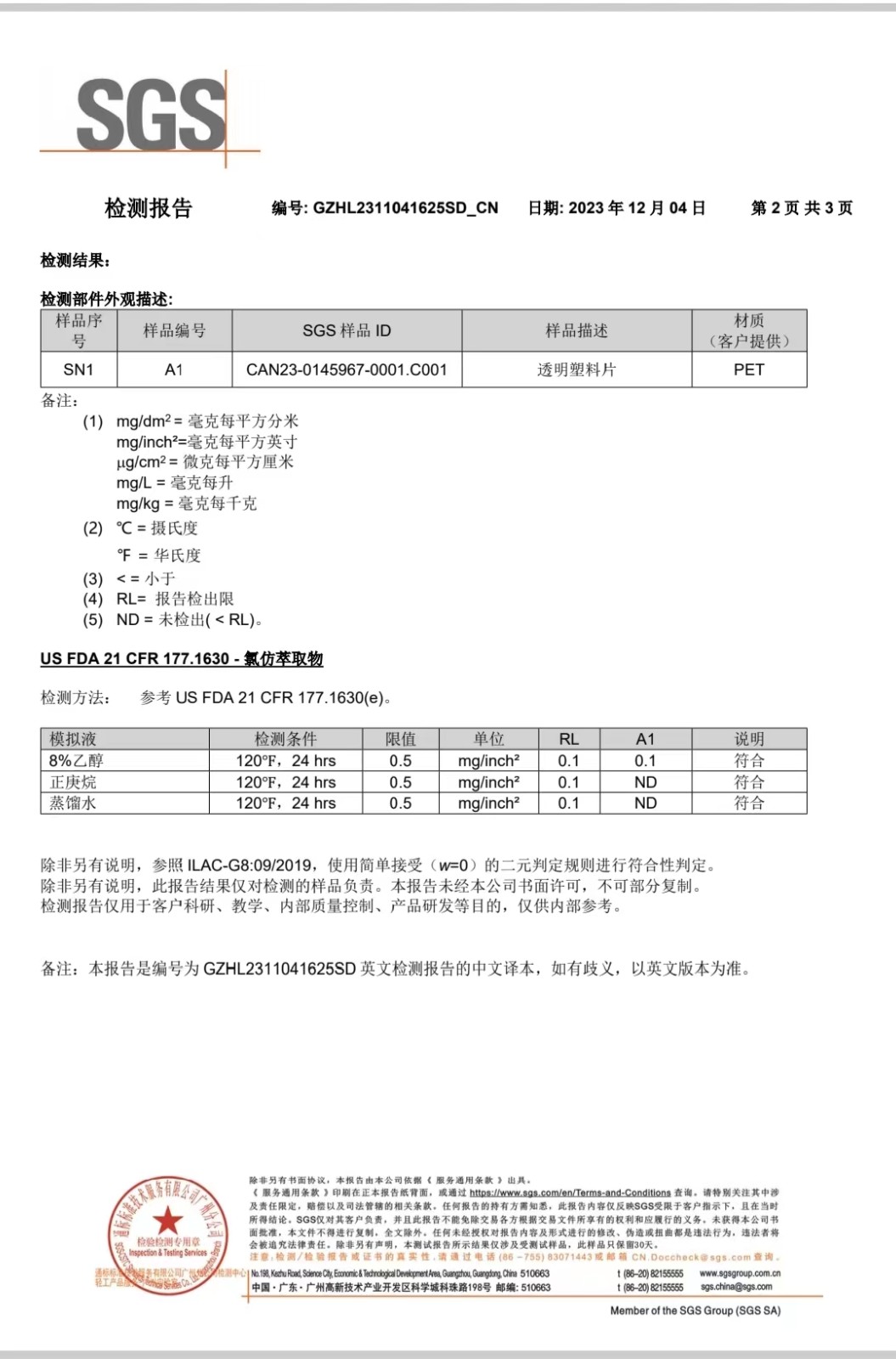

SGS 报告: 瑞康PP/PET透明抗菌薄片顺利通过国际接触食物包装标准和饮料酒精不大于8%包装标准的第三方认证!!!

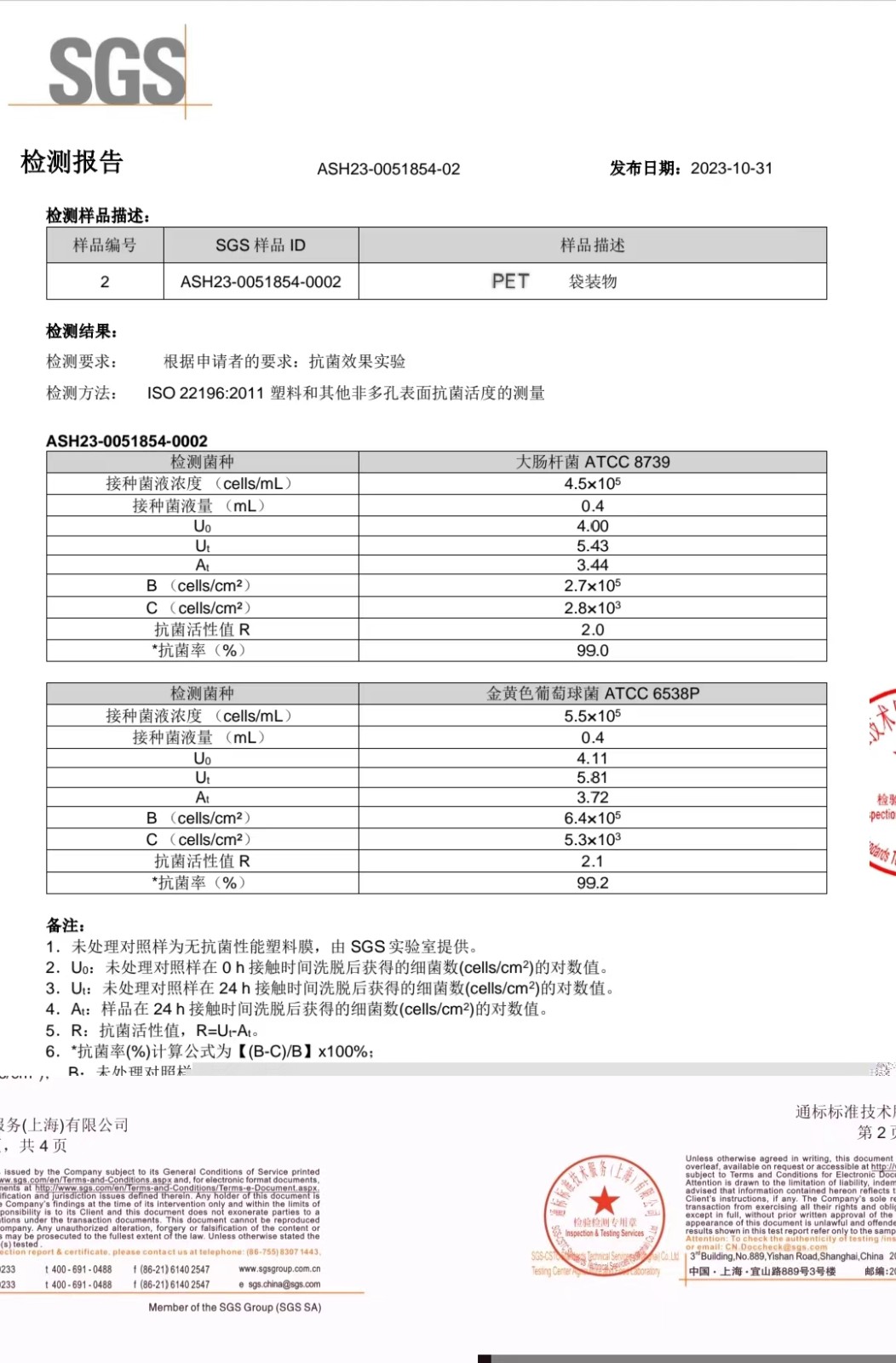

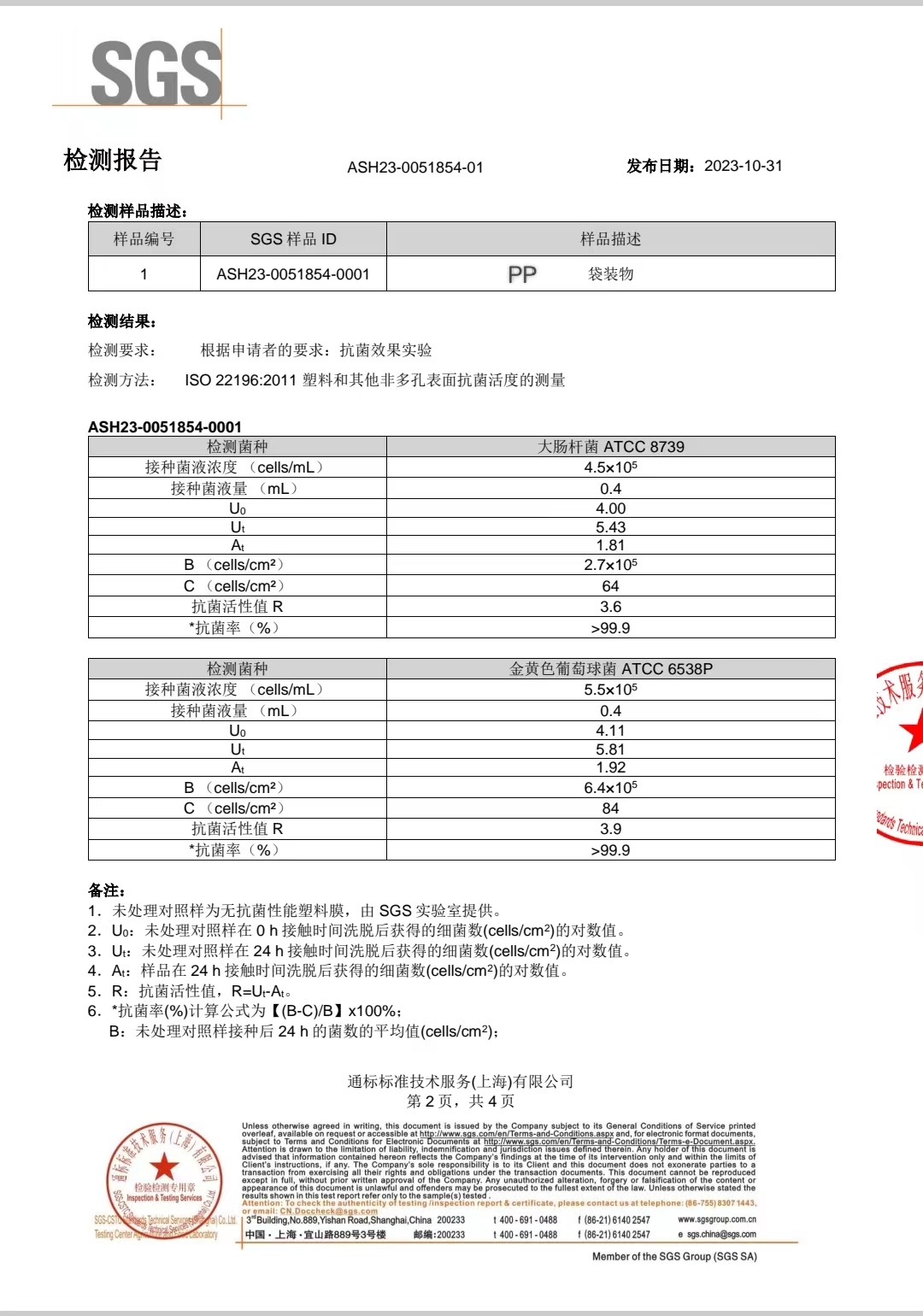

在PET和PP包装材料中加入0.6%瑞康发明的无毒抗菌剂制备成具有抗菌性能的PET和PP抗菌包装材料。如上为国际第三方检测公司SGS按照国际ISO标准测试了加入瑞康抗菌剂的PET和PP包装材料的抗菌性能测试报告。其结果表明,加入瑞康抗菌剂的包装材料抗菌效果完全满足国际抗菌标准,抗菌效果超越99%以上!

SGS国际标准认证瑞康无毒抗菌剂可以加入食品包装,蔬菜水果包装,快餐盒,饮料瓶/矿泉水瓶,化妆品瓶包装等。亦可用于与人接触过纤维,涂料等。

1

绍兴瑞康成功登入报刊

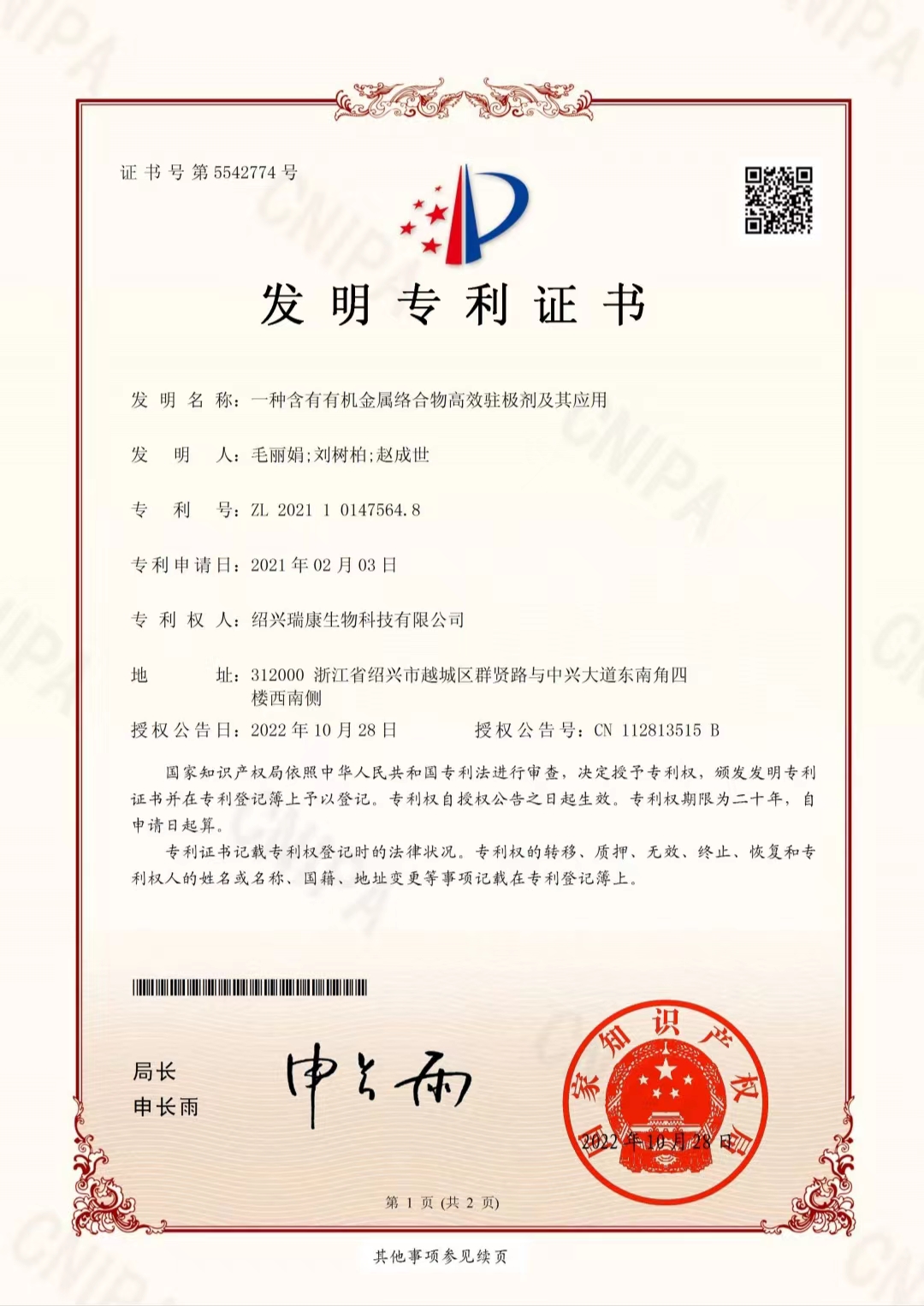

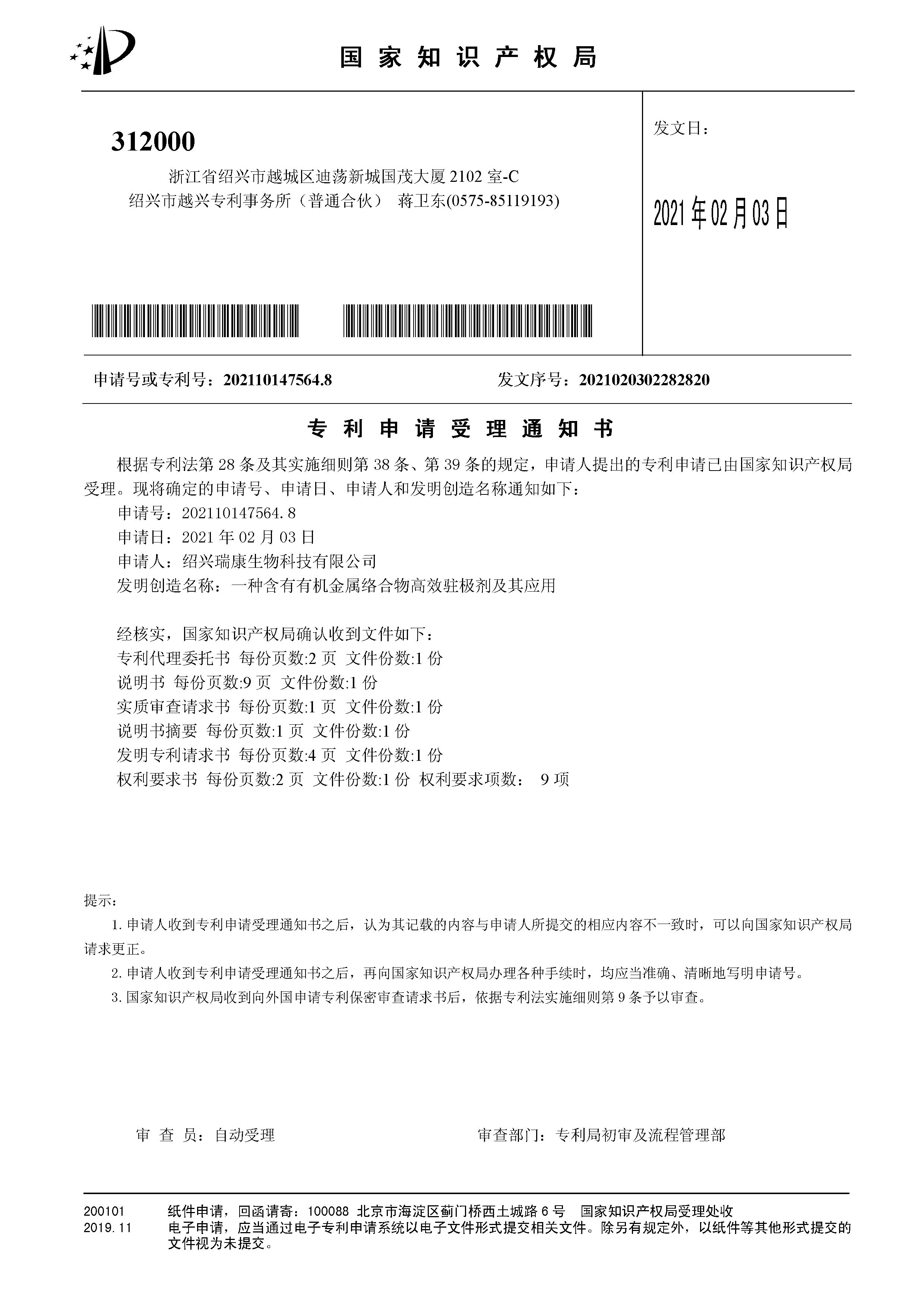

热烈庆祝瑞康又一发明专利授权!!!

Ruikang biology received the acceptance notice of the latest invention patent application again on February 3, 2021 after receiving two acceptance notices of invention patent application issued by the State Intellectual Property Office in November 2020 and December 2020. The name of the invention patent applied for this time is a high-efficiency electret containing organometallic complex and its application, and the accepted patent number is 202110147564.8.

The notification of the acceptance of invention patent application marks that Ruikang R & D team has opened a new chapter in the field of electret.

At the same time, Ruikang electret successfully passed the test requirements of gas mask and achieved the expected effect of gas mask. Ruikang always firmly believes in respecting innovation, adhering to innovative R & D, constantly challenging and moving towards higher-level excellence.

Ruikang team has made another historic milestone in the field of water-based lotion antibacterial agent antistatic agent: through unremitting efforts, Ruikang has successfully completed the lotion polymerization technology and developed high-efficiency water-based lotion antibacterial agent with antistatic effect at the same time!!!

As the Spring Festival approaches, the R & D team of Ruikang welcomes a test report from Arizona, a desert state in the United States, which has kept our R & D team waiting for two years.

In 2018, an auto parts manufacturer in the United States started a two-year exposure test in the Arizona desert using the auto parts made of rk-uv678a developed by Ruikang. As we all know, the climate and environment of Arizona desert in the United States are very bad, with the highest temperature of 45 ℃ and low temperature of - 20 ℃ in the whole year. In such a bad environment, after two years of exposure test, the product has not changed in color and color. It is far ahead of similar test products and has reached the GM international standard of the United States.

Each milestone is an update of experience, and the core technology can only come out step by step. Ruikang R & D team does not forget its original intention, always adheres to independent innovation and strives to be a leader in the industry.

On November 24, 2020, the 2020 annual meeting and standard review meeting of the aging method branch of the National Plastics standardization committee were held in Nanchang, Jiangxi Province. At this meeting, Dr. Mao Lijuan, chairman of Shaoxing Ruikang biotechnology, was hired as the communication member of the aging method sub Technical Committee of the National Plastics Standardization Technical Committee (SAC / tc15 / SC5). Among the few members nationwide, Dr. Mao has the honor to become the only member of the innovative polymer functional additives and participate in the formulation of the Standards Committee mentioned above. This is not only the great recognition of Dr. Mao's personal innovation ability, but also the encouragement of the innovation work of Ruikang technical team led by Dr. Mao.

Backed by science and technology, Shaoxing Ruikang biology has focused on the research and development of new polymer materials and achieved great industrial development. It has successively applied for 22 invention patents, including three international patents and eight Chinese invention patents. The polymer functional additives developed by our company are brand-new patented technological innovation products in terms of structure and performance. It fills the gap in the development of new polymer materials for the country. In particular, the new functional mother core structure of light stabilizer completely created by the patent recently issued by Ruikang jumps out of the functional structure of tetramethylpiperidine light stabilizer that has been used for half a century, and overcomes the shortcomings of previous alkaline high catalytic thermal degradation of polymer materials.

At present, with the development of China's plastic industry, according to the relevant documents and articles of association of plastic standardization issued by the state, Dr. Mao and his Ruikang team under his leadership will more firmly grasp the basic knowledge, abide by the relevant articles of association of the technical committee, actively participate in the standardization activities organized by the technical committee, earnestly perform the duties and obligations of the members, and contribute to the plastic standard industry.

Recently, Ruikang biotechnology, located in Doumen street, welcomed a group of R & D personnel from Zhejiang guxiandao Green Fiber Co., Ltd. to seek new high-performance additives used in the production of functional fibers. The fiber products developed by Ruikang biotechnology, such as anti yellowing and anti-aging additives, have aroused great interest of guxiandao company.

Yang Zhichao, chief engineer of Zhejiang guxiandao Green Fiber Co., Ltd., said that the polyester industrial yarn produced by guxiandao company is mainly used in military industry, fire control and ocean. Current customers have put forward some special requirements in these fields, such as corrosion resistance in the ocean, military aerospace processing of static electricity, signal transmission and other issues. They hope to cooperate with Ruikang technology company to form some special varieties of functional additives.

According to Dr. Mao Lijuan, chairman of Ruikang biology, at present, the application of functional additives for polymer materials covers almost all aspects of people's production and life, ranging from leather, fiber, coating and carpet to automobile, household appliances and aerospace. It is precisely because of the addition of these functional additives that the strength, hardness and other properties of product materials, as well as service life, shape and color can be guaranteed. For example, if some plastic products do not add functional additives, they will be powdered and broken quickly under the action of daily light and heat, and the function of the products will become empty talk. However, over the years, these functional additives almost completely rely on imports, and the international price is high. For example, the price of light stabilizer used in the production of some high-end materials has reached 500000 to 1 million yuan per ton.

At present, Ruikang biology has successfully developed hundreds of varieties of high-performance additives such as anti yellowing agent, light stabilizer, antioxidant, blending agent and coupling agent, and has obtained eight national invention patents, three international patents, one patent from the United States and one patent from Japan, and 14 national issued patents are in the process of approval. Enterprises have also participated in the formulation of national plastic aging standards. Among them, the newly developed steric adjustable light stabilizer overturns the functional structure of tetramethylpiperidine light stabilizer used in the United States and Japan for half a century, and can be applied to PVC, PC, polyester and other fields for the first time. It has superior light stability, color fastness, degradability and other properties, better product protection, and the overall service life is increased by more than 10%. More importantly, this innovative product will significantly lower the price and become more competitive in the market. At present, the market level of domestic functional additives can reach more than 100 billion, and the prospect is very promising. At present, Ruikang biological products have been produced in small quantities. It is expected that in the next stage, after the production capacity, site and other factors are in place, the sales will increase explosively.

Zhou Lingling, chairman of Yuecheng science and Technology Association, told reporters that first-class materials need first-class additives. Ruikang biology can not only make its own industrial chain bigger, but also help many of our plastic related material enterprises, including textile enterprises, to improve the function of materials and realize transformation and upgrading.

Ruikang Biotechnology: research and development of high-end additives, promising market prospects

On November 17, 2020, at the China synthetic resin new material industry development conference, Dr. Mao Lijuan, chairman of Shaoxing Ruikang, released the latest accepted invention patent achievement: the research and application of space steric adjustable weak alkaline light stabilizer, which was praised by the leaders of the Ministry of science and technology. This achievement was designed and invented by Dr. Mao himself and led the R & D team of Ruikang after more than five years of arduous efforts. It overturned the functional structure of tetramethylpiperidine light stabilizer, which has been used for half a century, and launched the original innovative space resistance adjustable weakly alkaline innovative stabilizer, so as to obtain more choices and opportunities for the development of new materials.

It is reported that HALS light stabilizer, which is widely used in plastics, rubber, coatings, paints, fibers and inks in the international market, was invented by Japan and the United States in the early 1970s and has been used today for half a century. Hindered amine (HALS) light stabilizer is obviously alkaline, and the surrounding steric hindrance is fixed. These properties determine that it cannot be used in PVC, polyester, polycarbonate, PU and other polymer materials. Hindered amine will react with these polymer materials and catalyze the degradation of polymer materials. In this way, it has to develop weakly alkaline light stabilizer in the derivation of hindered amine molecules, which is expensive.

The innovative chemical structure designed by Ruikang team is a weak base light stabilizer with adjustable steric resistance. The structure is stable, the steric resistance can be controlled, and the electronegativity can be regulated. Such a flexible structure makes it widely used in all kinds of polymer materials and provides better weather resistance protection for polymer materials. Therefore, Ruikang achievements have great application and promotion value in the development of new material industry in the future.

Shaoxing Ruikang Biotechnology Co., Ltd., founded in 2013, is a high-level talent enterprise settled in Yuecheng. The expert team of the company has many years of experience in large international companies in North America. Ruikang has never stopped on the road of innovation.

(source: District Science and Technology Association)